Electrochemical cleaning NITTY GRITTY

- Clinox system for cleaning TIG welds

- Marking of stainless steel and other materials

- Passivation tester, CrNi

- Cleaning and passivation

Passivation of stainless steel

Clinox REC, SURFACE, SURFACE Plus, POWER, PRO and ECO machines

Enable immediate, ecological and effective treatment of stainless steel welds, which are performed by TIG, pulsed MIG methods

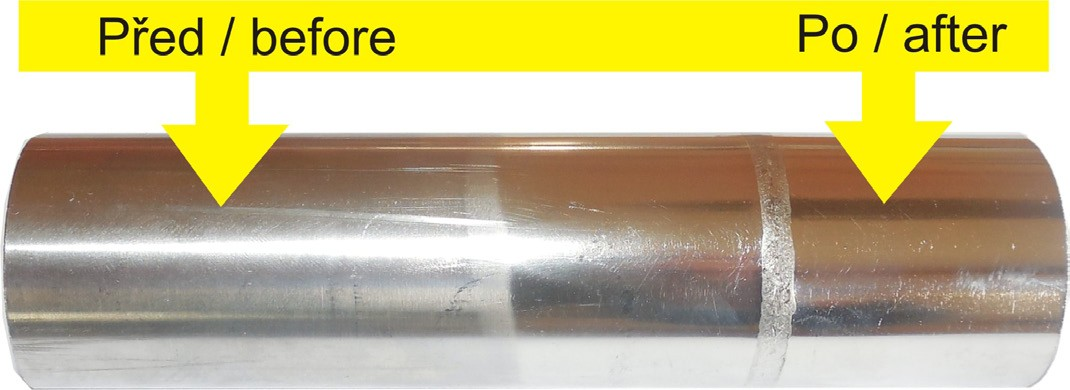

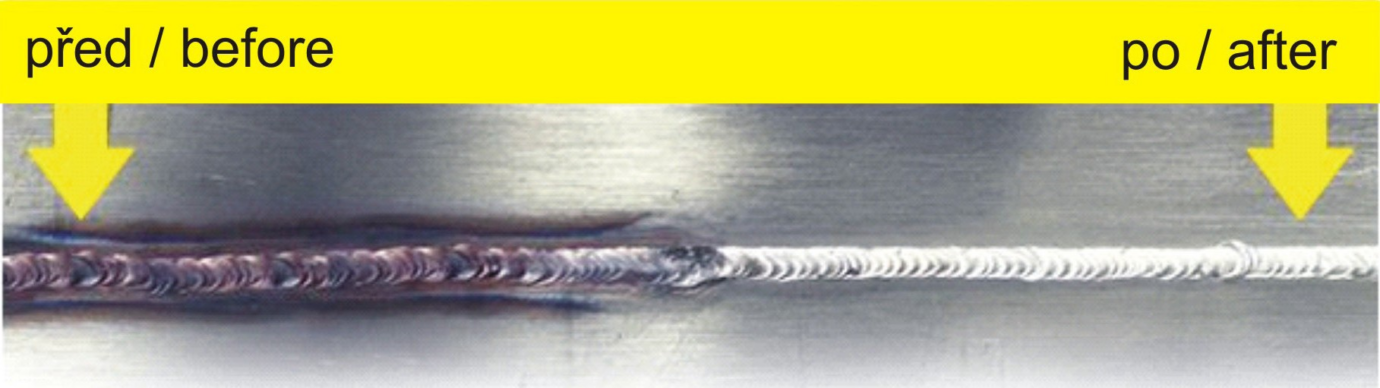

The Clinox system, through an immediate electrochemical reaction, ensures the cleaning, passivation and polishing of every stainless steel weld regardless of treatment. The process itself is very fast without affecting the surrounding material and completely safe for the operator.

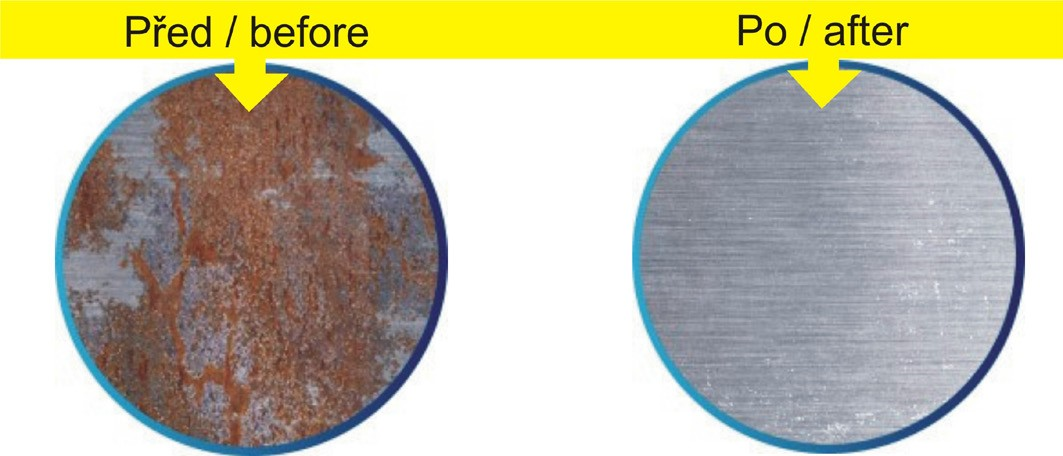

Surface treatment

Stainless steel offers exceptional mechanical properties that make it irreplaceable. Most operators take great care in mechanical (cutting, bending, etc.) and thermal (welding, spot welding, etc.) operations, but tend to neglect the finishing touches that are necessary to restore the original properties of the material – durability and corrosion resistance.

Treatments that steel can undergo:

- Degreasing

- Pickling

- Pasivace

TIG.CLINOX offers a number of advantages compared to conventional, outdated treatment methods.

Advantages over mechanical pickling by grinding

- does not damage the finish

- does not release metal particles (aluminum and others) into the atmosphere, does not pollute the material

- cleans and passivates evenly

- reduces the cost of consumables and improves working conditions

- less danger due to the absence of moving parts that can injure the operator

Advantages over chemical staining with gels/pastes

- much faster process of instant result verification

- better working conditions, the user can work inside the building

- does not damage the surface treatment of the material

- does not produce fumes harmful to the environment or operators (only in case of TIG.CLINOX PRO; TIG.CLINOX ECO model must be used in conjunction with extraction)

- BOMAR solution residues can be neutralized with INOX FIT liquid and can be removed with a paper towel or a wet cloth. The part does not have to be difficult to clean, which means that no toxic waste is produced.

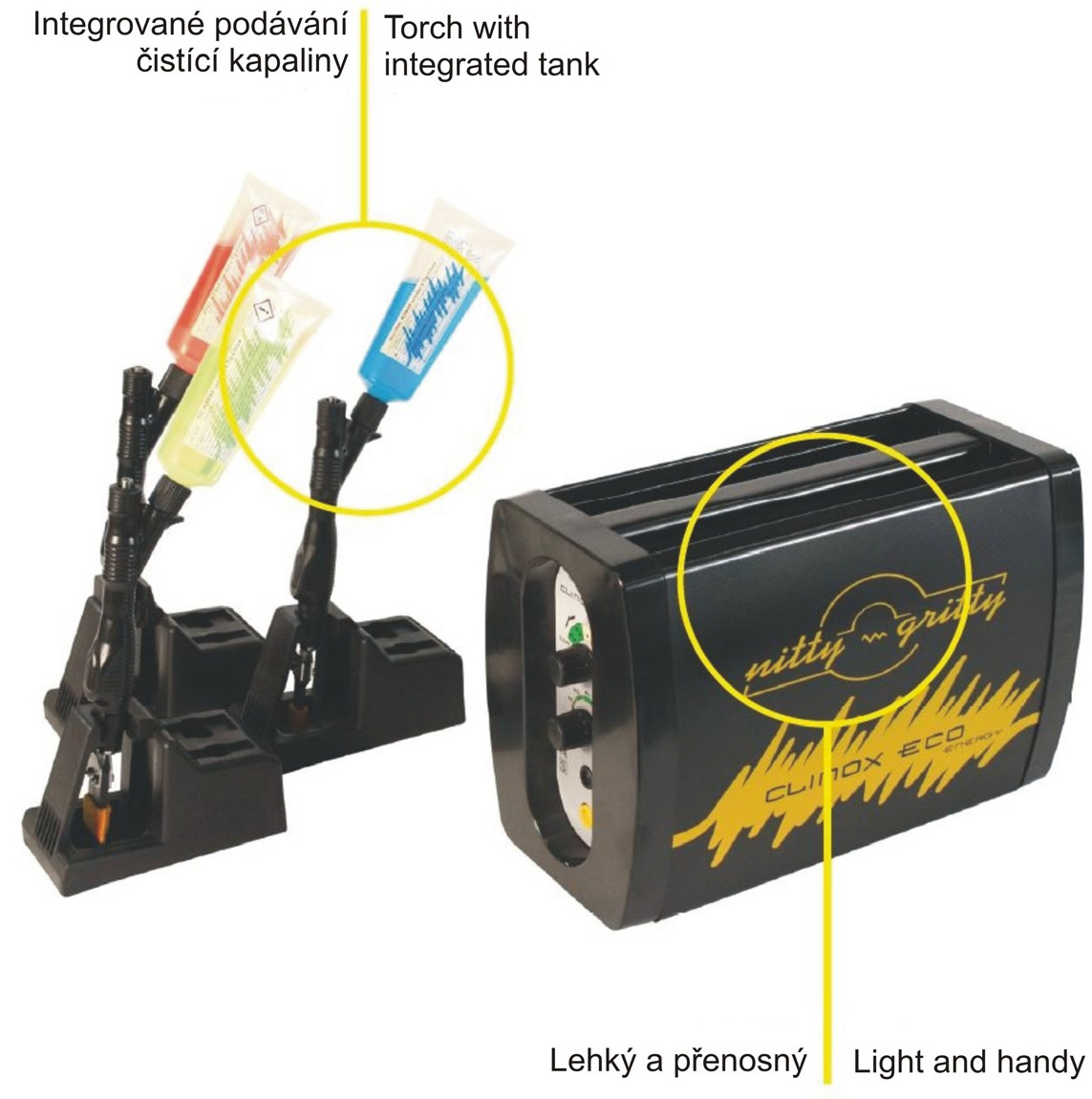

Torches

- Ergonomic

- Easy replacement of consumable parts

- Articulated system that saves cable wear and extends the life of the torch

CLINOX

INVERTOR CLINOX ECO ENERGY

The Clinox Eco Energy machine is a light and handy helper in the energy range. Thanks to the inverter technology, it ensures a real productivity of 96% (instead of 44% for machines with a transformer motor). It is equipped with a patented burner with manual dosing from an integrated container. Using a new brush makes it easier to reach hard-to-reach places.

In addition, the Clinox Eco Energy, like many other Clinox machines, allows marking for stainless steels, galvanized steels, chrome steels, carbon steels, aluminum alloys, brass, copper and titanium.

CLINOX POWER

Clinox Power is the ideal solution for immediate ecological treatment of TIG, MIG/MAG, MIG pulse, laser, resistance, orbital and plasma welding. The modern Clinox Power technology, through an immediate electrochemical reaction, ensures the cleaning, passivation and polishing of every stainless steel weld, regardless of surface treatment and without loss of time, without spots and rings, and completely safe for the operator.

Clinox Power is a professional system designed for companies that need high productivity: thanks to inverter technology, it ensures a high efficiency of 96% (instead of 44% for machines with conventional transformers) and it is the only machine equipped with a patented large torch with automatic electrolyte dosing.

Other advantages of Clinox Power are:

- exhaust fumes

- quick change of optional tips

- watermarked pickling solution tank automatic liquid dosing pump patented second burner with integrated reservoir with manual dosing, able to work simultaneously with a larger burner, doubling productivity

- brush for easier access to hard-to-reach places

In addition, the Clinox Power, like many other Clinox machines, allows marking and white marking of stainless steel, galvanized steel, chrome steel, carbon steel, aluminum, brass, chrome plastic, copper and titanium.

Clinox Pro ENERGY

Clinox Pro Energy for immediate ecological treatment of TIG, MIG pulse, laser, resistance, orbital and plasma welds. The modern Clinox Pro Energy technology ensures, through an immediate electrochemical reaction, the cleaning, passivation and polishing of every stainless steel weld, regardless of surface treatment

and without loss of time, without spots and rings, and completely safe for the operator.

Thanks to inverter technology, the professional Clinox Pro Energy system ensures a high efficiency of 96% (instead of 44% for machines with conventional transformers) and is equipped with a patented large torch with automatic electrolyte dosing.

Other advantages of Clinox Pro Energy are:

- fume extraction

- quick change of optional tips

- pickling solution tank with watermark automatic liquid dosing pump

- patented second burner with integrated reservoir with manual dosing, able to work simultaneously with the larger torch, doubling productivity

- brush for easier access to hard-to-reach places.

In addition, the Clinox Pro Energy, like many other Clinox machines, allows marking and white marking of stainless steel, galvanized steel, chrome steel, carbon steel, aluminum, brass, chrome plastic, copper and titanium.

Clinox SURFACE and SURFACE plus

Clinox Surface is the ideal solution for immediate ecological treatment of both welds (welding methods: TIG, TIG with filler metal, pulsed arc, MIG, laser, resistance, plasma) and large surfaces. Modern Clinox Surface technology, using an immediate electrochemical reaction, ensures safe pickling, passivation and polishing of any stainless steel for the operator, regardless of its treatment and without leaving rings and wasting time.

Clinox Surface, a professional device, intended for companies focusing on the treatment of large areas, is the only machine available equipped simultaneously with a patented large torch with automatic electrolyte feeding, a vapor exhaust system, a simultaneously cooling tool, quick-change tools, a pickling solution tank with an indicator level, an automatic pump for liquid dosing, a brush for reaching hard-to-reach places and a patented smaller torch with manual dosing control and an integrated tank capable of working simultaneously with a larger burner (doubling productivity).

But that’s not all!

With a 10-centimeter tool and a 6-meter extension cable, the Clinox Surface can work directly on the surface. In addition, thanks to a special socket and a powerful converter, the Clinox Surface can be connected to special brushes intended for extensive surface treatments (e.g. silos in the food and wine industry). Like all machines in the Clinox range, the Clinox Surface can do black (white marking) on stainless steel.

Marking of stainless steel and other materials

Inox Mark

The Inox Mark electrochemical marking system permanently marks stainless steel and other materials (galvanized steel, chrome steel, carbon steel, aluminum, brass, copper, titanium) using an electrochemical reaction. The marking is in high resolution, compared to the mechanical way, it is high quality, fast and durable. Despite the immediate electrochemical reactions, the marking is much cheaper than a laser or screen printing system. There are two possible types of marking thanks to Inox Mark: black marking and white marking for stainless steel.

Marking made by the Inox Mark system has a mechanical and chemical and corrosion resistance higher than laser and screen printing systems. The high stability of marking, together with the complete absence of solvents, acids or other dangerous substances, allows the device to be used also in the food and pharmaceutical industries.

MULTI Mark

Thanks to a special procedure, Multi Mark is the first device in the world that allows you to perform “black marking” on aluminum. Multi Mark is equipped with a converter and a touch screen. Marking takes place by an immediate electrochemical reaction, which compared to screen printing or laser marking, offers low costs along with high resolution marking on surfaces such as: stainless steel, galvanized steel, chrome steel, carbon steel, aluminum, brass, chrome plastic, copper and titanium.

Multi Mark offers two types of marking: black and white marking (localized electrical erosion). The titanium surface marking is available in two different color variants.

Advantages of the Multi Mark device:

- higher mechanical and chemical resistance compared to screen printing and laser marking,

- speed,

- corrosion resistance, the marked part becomes more resistant than the original surface (tests available on request),

- without heating the surface,

- the possibility of marking large areas on thin layers without deformation of the metal,

- marking quality comparable to laser,

- maximum flexibility thanks to two different matrices:

- fixed with several repetitions and

- disposable, created on a special printer.

The high stability of the marking together with the complete absence of solvents, acids and other hazardous substances after the completion of the process, enable the use of the Multi Mark machine in the food, medical and cosmetic industries (ion transfer and release tests available on request).

HANDY PRINT

The Handy Print marking system, using an immediate electrochemical reaction, at much lower costs than laser or screen printing marking, ensures high quality marking on such surfaces as:

- stainless steel,

- galvanized steel,

- chrome steel,

- chrome plastics.

Handy Print is the first battery-powered machine for electrochemical marking of stainless steels. The 40-minute battery life makes the Handy Print an ideal solution for marking during work on stainless steel products.

The strengths of the Handy Print marking system are:

- mechanical and chemical resistance higher than laser or screen printing;

- speed; corrosion resistance, where the marked part is more resistant than the base metal (tests available on request);

- no heat input, thus preventing deformations when marking large logos and trademarks on thin materials;

- the quality of detail is comparable to a high-resolution laser;

- maximum flexibility with the possibility to use either:

- of permanent matrices or

- disposable dies made through a press kit;

- high marking stability, together with the complete absence of solvents, acids or any hazardous substances, allow the machine to be used also in the food, medical and pharmaceutical sectors (ion transfer and release tests available on request).

Passivation tester, CrNi

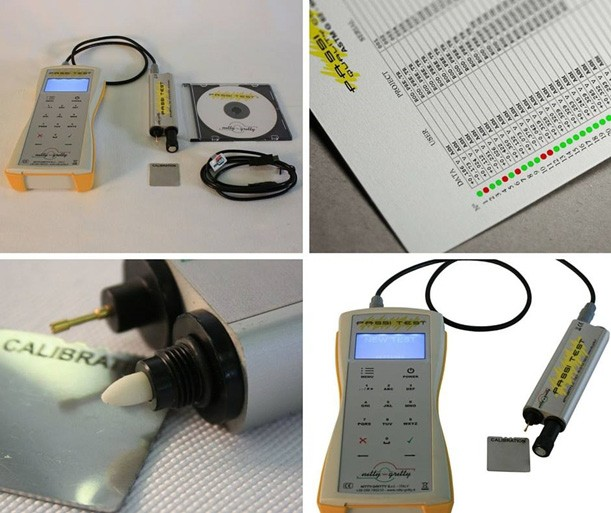

Pass Test Plus

Passivation test Plus is a tool designed for those who need to know the true quality of stainless steel and its resistance to corrosion. It consists of a “probe” that will be placed on the surface to be tested – containing an electrochemical system, reading and storing data in an external unit. This test, which is non-destructive, without damaging the material, is very simple and the result is evaluated within 20s in a numerical value, while other passivation tests, which are purely chemical, are based on the interpretation of colors, thus providing a strongly subjective reading, often distorted by surface impurities. Passi test Plus gives the exact numerical result.

Passivation test Plus is a system that is calibrated so that the zero value is the default neutral point: if the value is greater than zero, then the stainless steel is passivated, if the value is less than zero, there is little or no passivation.

In addition: Passi test Plus has microprocessor cards, a wide-angle screen, and an internal memory that allows you to perform the test and simply check it without saving the data. It is possible to set different usernames and passwords so that each user has reserved access to the certification function; once logged in, they can enter the batch number and serial number, which will then be linked to the operator with the date and time of the test. For the reason that they can obtain a report on treatments that have been carried out to verify, for example, the increase in the passivation value of stainless steel after surface treatment. Thanks to the software equipment, the report can be downloaded as a PDF file in any PC, simply via a USB connection.

The use of the Passi test Plus is thus intended not only for the inspection of stainless steel welds, but in general for those who use and manufacture stainless steel and want to check and prove its true quality.

Electrochemical polishing using E-Polishing Box

allows to triple the polishing speed of small geometrically complex objects such as springs, screws, various special parts, etc.

Cleaning and passivation of stainless steel using wipe sets

Pick & Clean

is a simple solution for pickling and passivating stainless steel

Stainless steel cleaning with Pick & Clean is really ideal for those who need to treat stainless steel welds in hard-to-reach places or places where electrochemical cleaning equipment cannot be used.

Apply Pick tape to the stainless steel welds to be treated and the stainless steel welds will be treated within a few minutes. Subsequently, we neutralize the surface with the Clean spray and treat it against future corrosive phenomena.

Finally, wipe the surface with a paper towel. This procedure is fast, safe and completely environmentally friendly.

DEOX & FIT

Passivation of stainless steel

It is a product that enables the oxidation and passivation of stainless steel. It is intended for everyone who needs to influence this process. Its use is simple.

We will use a DEOX wipe on the stainless steel parts to be treated. Within a few seconds, the oxidation will disappear from the surface of the stainless steel. Then we neutralize the surface with the Fit spray and treat it against future corrosion phenomena. Finally, wipe the surface with a paper towel.

Three quick steps to easy surface treatment. This procedure is fast, safe and completely environmentally friendly.