Plasmas manual cutting

Manual plasma cutters are portable machines with a torch and compressed air supply. Thermal separation of the material by plasma technology is used, so no flammable gas is needed and no open flame is used, unlike our ALFATEC plasma tables, where there is the option of an extended variant of material separation by flame (acetylene/oxygen). This results in significantly lower thermal effects on the split material and a narrower cutting joint in the material.

The constant development of plasma sources leads to their reduction and increase in performance. Plasma, if it has enough compressed air, is a relatively simple and safe source that can divide various electrically conductive materials, including polluted or corroded ones. Our plasma sources can turn off the fan when not needed for cooling. They are easy to operate and also allow cutting perforated sheets. In our PDF catalog we list the parameters of the individual machines, the strength and type of split material, including the required air consumption. Compressed air is a more accessible and safer medium than the open flame used in autogenous material splitting, and there is no need to worry about pressure cylinders.

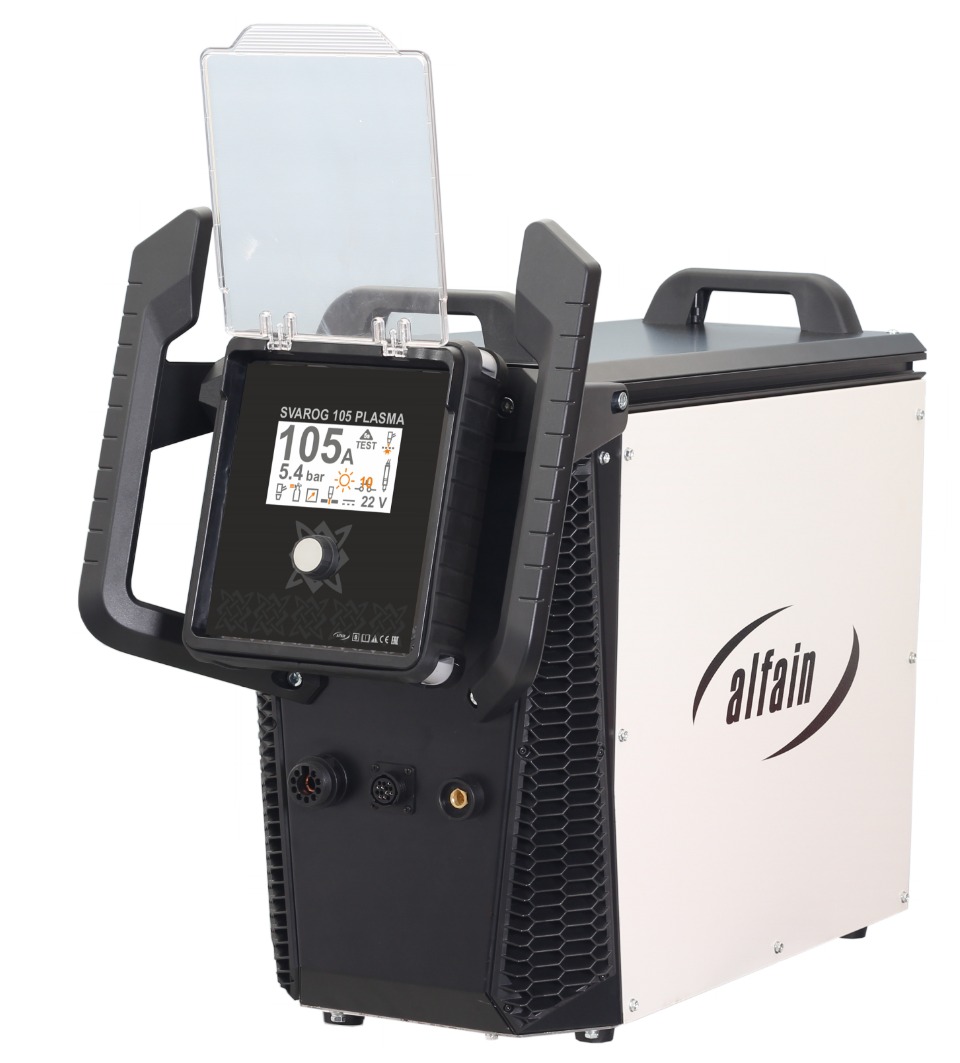

Svarog 85, 105 & 125 PLASMA Line

Our newest plasma Line uses modern technology to divide material through a thin beam of plasma gas. SVAROG 85-105-125 PLASMA are equipped with a proportional valve, which allows precise setting of the required working gas pressure and display of the pressure value on a large, clear, color display. All the necessary important information is available at a glance. The proportional valve makes it possible to precisely set the required pressure or gas flow and enables high cutting accuracy. This technology has several advantages over other methods:

- High cutting speed

- Quality cut with a minimal area of altered material structure

- Smaller thermal deformation of the cut material

- The possibility of cutting carbon and high-alloy, stainless steel and non-ferrous metals

- The method does not require any special gases

- Low costs

SVAROG PLASMAS are intended for high-quality cutting of materials thickness up to 42 mm carbon steel. Productive cutting of carbon steel is possible up to a thickness of 35 mm. With lower demands on cut quality, material up to 55 mm thick can be cut through (separated).

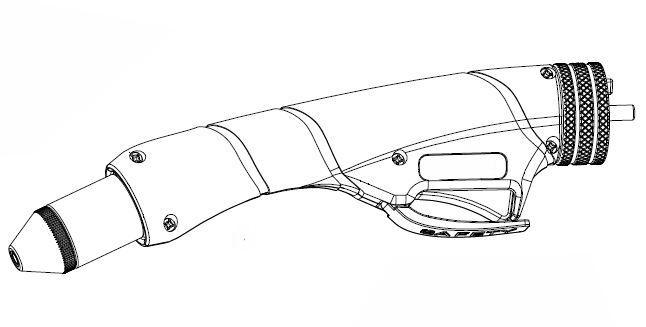

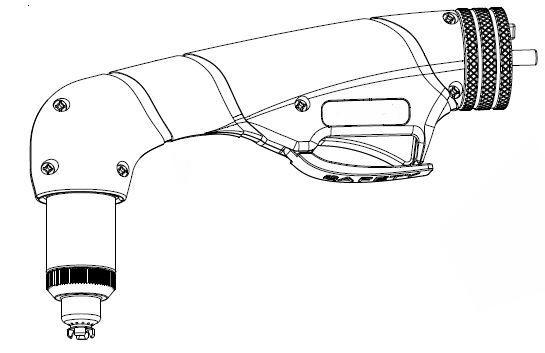

We have currently innovated the torches and launched the new SVH 105 and SVH 125 torches on the market.

Manual torch SVH-105

Gas cooling

- Current range / Current 20 – 105A

- Duty cycle 60% 105A

- Gas Air/N2

- Pressure

- Cutting 5,0-5,5 bar

- Gooving 3,5-4,5 bar

- Gas flow 240 l/min

- Post-gas 45s

- Ignition bez HF

Manual torch SVH-125

Gas cooling

- Current range 40 – 150A

- Duty cycle 60% 125A

- Gas Air/N2

- Pressure

- Cutting 5,0-5,5 bar

- Grooving 3,5-4,5 bar

- Gas flow 295 l/min

- Post-gas 45s

- Ignition bez HF

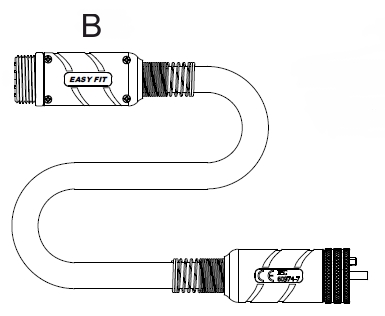

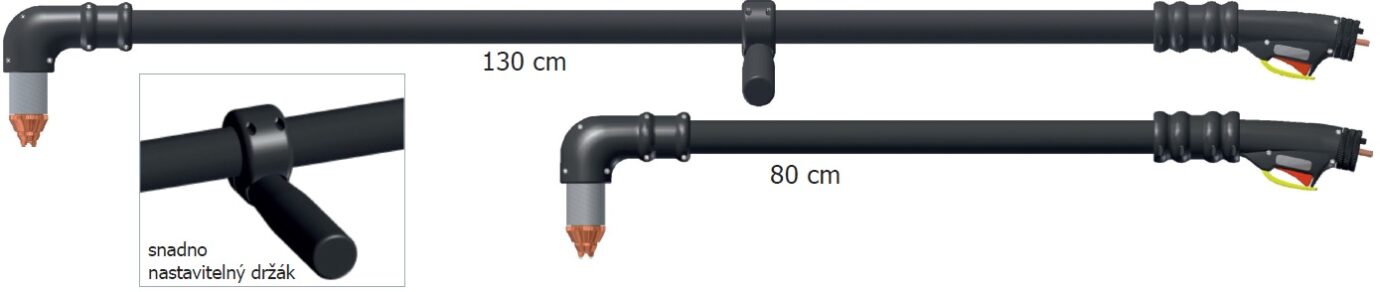

Common coaxial cable and 6 m extension of the common cable

Both powerful types of plasma torches use a common 6.7 meter coaxial cable. This cable can be extended by another 6 meters. We have carefully tried, tested and measured everything.